|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Click here for updates. Click here to send me an email.

The Tofu Truck is

Kahn Landscaping LLC's

1987 Ford F350 diesel dually. I call it the Tofu Truck because I run it on

vegetable oil, usually soybean.

The Tofu Truck is

Kahn Landscaping LLC's

1987 Ford F350 diesel dually. I call it the Tofu Truck because I run it on

vegetable oil, usually soybean.It uses a 6.9L International diesel engine, normally aspirated.

The newer Ford light trucks use a single 40 gallon fuel tank, which makes running on vegetable oil a little more difficult. Even in the summer, one needs to start a diesel engine on petroleum-based diesel until the engine warms up (unless you run biodiesel.) On vehicles with a single fuel tank, one needs to install a separate tank so you have one for petroleum diesel and one for veggie oil. My 1987 has two fuel tanks and a rocker switch in the cab to switch between them. There is an 18 gallon primary tank in front and a 14 gallon reserve tank in back. I keep the rear tank filled with petroleum diesel. There are three phases to my testing the truck on veggie oil:

1. Run the front tank until nearly empty. Then load two gallons of fresh straight

vegetable oil (SVO) one gallon at a time. I loaded the first gallon, drove about five miles to observe behavior,

then I loaded the second gallon and drove about another 20 miles. After no negative effects, I proceeded to phase

two:

1. Run the front tank until nearly empty. Then load two gallons of fresh straight

vegetable oil (SVO) one gallon at a time. I loaded the first gallon, drove about five miles to observe behavior,

then I loaded the second gallon and drove about another 20 miles. After no negative effects, I proceeded to phase

two: 2. Buy 4-35 lb. (about 4.5 gallons each) of fresh soybean oil from a local wholesale club. The price was

relatively close to that of petroleum diesel in the southern New Hampshire area, about $3.00 per gallon. After

using almost the whole 20 gallons (2-1 gallon containers, then 4-4.5 gallon containers) of soybean oil (about 250

miles of driving) I proceeded to phase three:

2. Buy 4-35 lb. (about 4.5 gallons each) of fresh soybean oil from a local wholesale club. The price was

relatively close to that of petroleum diesel in the southern New Hampshire area, about $3.00 per gallon. After

using almost the whole 20 gallons (2-1 gallon containers, then 4-4.5 gallon containers) of soybean oil (about 250

miles of driving) I proceeded to phase three: 3. I obtained about three of the 4.5 gallon jugs of waste vegetable oil (WVO) from a local

restaurant. I created a pump and filter system to filter the WVO down to 25 microns.

As of this writing (9/20/06) I put about 2.5 gallons of WVO in the front tank, which has somewhere between four and

five gallons of fresh SVO in it. The truck has been idling for a little over an hour now, just to make sure there

are no "issues." If there are no issues after about 500 miles of driving on WVO, I will proclaim the entire test

a success.

3. I obtained about three of the 4.5 gallon jugs of waste vegetable oil (WVO) from a local

restaurant. I created a pump and filter system to filter the WVO down to 25 microns.

As of this writing (9/20/06) I put about 2.5 gallons of WVO in the front tank, which has somewhere between four and

five gallons of fresh SVO in it. The truck has been idling for a little over an hour now, just to make sure there

are no "issues." If there are no issues after about 500 miles of driving on WVO, I will proclaim the entire test

a success.Click on any image to enlarge it:

Why am I doing all this?

It consists of a clear intake hose on the right, a filter, connecting tubing, a pump, and a green discharge hose on

the left. The jugs for waste vegetable oil (WVO) and filtered waste vegetable oil (FWVO) are below the table.

I will be mounting the refinery on its own stand, probably with wheels so it can easily be moved about, not that it

is that heavy.

It consists of a clear intake hose on the right, a filter, connecting tubing, a pump, and a green discharge hose on

the left. The jugs for waste vegetable oil (WVO) and filtered waste vegetable oil (FWVO) are below the table.

I will be mounting the refinery on its own stand, probably with wheels so it can easily be moved about, not that it

is that heavy. The pump is a 1/12 hp Sears utility pump which I paid about $80 for. The little red warning label says, among

other things, that it is only supposed to be used for water. However it also says that you're not supposed to

run the pump dry, and that before each use you're supposed to put a teaspoonful of oil into the pump intake. Well,

guess what I am pumping with this pump, hmmm?

The pump is a 1/12 hp Sears utility pump which I paid about $80 for. The little red warning label says, among

other things, that it is only supposed to be used for water. However it also says that you're not supposed to

run the pump dry, and that before each use you're supposed to put a teaspoonful of oil into the pump intake. Well,

guess what I am pumping with this pump, hmmm? This filter is, you guessed it, a whole-house water filter system which I also bought at Sears for about $40.

It filters water down to 25 microns. We use a similar unit on our house as a pre-filter for the water. I imagine it

should not allow anything larger than 25 microns suspended in vegetable oil to pass through, either. Well, if

all this lack of following directions gets you nervous, just stay tuned for the long-term results.

This filter is, you guessed it, a whole-house water filter system which I also bought at Sears for about $40.

It filters water down to 25 microns. We use a similar unit on our house as a pre-filter for the water. I imagine it

should not allow anything larger than 25 microns suspended in vegetable oil to pass through, either. Well, if

all this lack of following directions gets you nervous, just stay tuned for the long-term results.The tubing between the pump and filter is ordinary cream-colored hot-cold PVC. The intake is some clear plastic tubing I had lying around. It helps me see if the pump is drawing correctly. The discharge hose is a regular, short section of reinforced garden hose that came with the pump.

These jugs are the 35 lb (4.5 gallon) containers that the fresh vegetable oil comes in. When I pick it up from

the restaurant, they give it to me in 5 gallon pails or directly in one of these jugs. I pump the WVO from a pail

or jug into one of the 35 lb jugs labeled "FWVO25," which means waste vegetable oil filtered down to 25 microns.

These jugs are the 35 lb (4.5 gallon) containers that the fresh vegetable oil comes in. When I pick it up from

the restaurant, they give it to me in 5 gallon pails or directly in one of these jugs. I pump the WVO from a pail

or jug into one of the 35 lb jugs labeled "FWVO25," which means waste vegetable oil filtered down to 25 microns.Any questions?

Well, partly it is politics and partly it is business.

The politics includes environmentalism. Long before I was old enough to drive, my mother instilled in me an interest in and concern for the environment. We would go down to the town highway department where the recycle bins were and would drop off our newspapers, plastic bottles, and we would sort our glass bottles by color.

Later in life, after I graduated with my undergraduate degree in computer systems engineering, I developed an interest in alternative sources of energy. I looked into wind power, solar power (including photovoltaics), and alternatives to fossil fuels including diesel substitutes. The original design by Dr. Rudolf Diesel for a compression-ignition engine was supposed to run on vegetable oil, so farmers who lived in remote areas where petroleum was not readily available, could "grow their own fuel." He demonstrated a compression-ignition engine running on peanut oil in 1900 at the Paris World's Fair.

Last year (2005) a man who owns a restaurant in Nashua bought two diesel-powered VW Beetles. He converted his cars by adding an auxilliary fuel tank and tank and fuel line heaters. I will probably have to do that if I continue using WVO in the winter. Anyway he's been running his cars on WVO from his own restaurant for an entire year. So I know there is a long-term track record.

Well, as part of my running for office I get a lot of candidate surveys asking my position on this and that, and I responded to one survey from the Organic Consumers Association. I did not do very well, earning only a 21% rating. This was largely due to my libertarian politics. But to their credit, they gave me lots of room to explain my answers. You see, they were looking for government intervention in regulating what gets to be called organic, subsidies for organic farmers, and so on.

I don't believe in allowing the fox to guard the henhouse, but the survey did inspire me to pursue the use of WVO for environmental reasons, political reasons (the publicity) and business reasons. I save money on fuel, the restaurant saves money on disposal costs, I help the environment, and I don't support the terrorists in the Middle East.

For more information, or a photo-op, please visit either my political website or my business website.

| 07/14/10 | It's been three months since I started parking the Tofu Truck on the concrete pad. Still no ill effects. |

| 04/29/10 | Today marks exactly two weeks after I started parking the dump truck on the concrete pad section. I've parked with the front wheels on the pad, rear wheels on the pad, including a couple of days where five yards of bark mulch also was in the truck. Also the weather has been typical New England all the way. This past week we've experienced all four seasons, from a snow flurry to temperatures over 80 degrees Fahrenheit. Last night the temperature dropped into the mid-twenties. Of course, two weeks isn't two years, but the pad appears to be holding up well enough that I will proceed with the next pad section. |

| 04/01/10 |

This is a Coleman 19.2 volt cordless drill I bought at an auto parts store near us. It was $50 with an effective value of $25 after

mail-in rebate (which by the way I don't remember receiving)

This is a Coleman 19.2 volt cordless drill I bought at an auto parts store near us. It was $50 with an effective value of $25 after

mail-in rebate (which by the way I don't remember receiving)

At issue is this power pack. I figured the weak link they would try to soak me on was to sell me a good drill with a lousy battery pack

hoping to suck me in to buying a replacement pack and that is where they would make their money. Well, I was right about one thing.

At issue is this power pack. I figured the weak link they would try to soak me on was to sell me a good drill with a lousy battery pack

hoping to suck me in to buying a replacement pack and that is where they would make their money. Well, I was right about one thing.

What did I have to lose? This is what was found pulling the power pack apart. Some really lousy NiCd cells which showed signs of

corrosion (see the bubbling?) As was stated before, I was right about one thing. I took the old battery pack to a number of local

hardware stores and home centers and the consensus was they had power packs that fit the drill, and they had power packs that were

19.2V, but they didn't have one that was both!. I would gladly have paid the $80 for a new NiMH pack that

fit and I didn't have to solder.

In keeping with my "never let it die" mentality and

What did I have to lose? This is what was found pulling the power pack apart. Some really lousy NiCd cells which showed signs of

corrosion (see the bubbling?) As was stated before, I was right about one thing. I took the old battery pack to a number of local

hardware stores and home centers and the consensus was they had power packs that fit the drill, and they had power packs that were

19.2V, but they didn't have one that was both!. I would gladly have paid the $80 for a new NiMH pack that

fit and I didn't have to solder.

In keeping with my "never let it die" mentality and  at built-in obsolesence, I decided to build one.

Rechargeable batteries are 1.2V for some reason and it doesn't matter whether they are NiCd, NiMH, or LiIon, they are 1.2V.

The good news is no one in the built-in obsolesence crowd has changed the laws of physics, and 1.2V coming from a NiCd is the same as

1.2V coming from a NiMH battery, and as long as the battery supplies enough current then it should work as long as it fits in the old

power pack case. AAA batteries would have fit better but not lasted long enough. The AA batteries were a better choice, CVS sold

them for $10 for a four-pack...and they

fit! I soldered 16 (1.2x16=19.2) of them end-to-end (series), at built-in obsolesence, I decided to build one.

Rechargeable batteries are 1.2V for some reason and it doesn't matter whether they are NiCd, NiMH, or LiIon, they are 1.2V.

The good news is no one in the built-in obsolesence crowd has changed the laws of physics, and 1.2V coming from a NiCd is the same as

1.2V coming from a NiMH battery, and as long as the battery supplies enough current then it should work as long as it fits in the old

power pack case. AAA batteries would have fit better but not lasted long enough. The AA batteries were a better choice, CVS sold

them for $10 for a four-pack...and they

fit! I soldered 16 (1.2x16=19.2) of them end-to-end (series),

stole the contact point from the tip of the old NiCds (not in the

picture above because I already stole it) and put the old thing together...and it works :-) stole the contact point from the tip of the old NiCds (not in the

picture above because I already stole it) and put the old thing together...and it works :-)

|

03/24/10 |

This picture shows some driveway damage caused by the Tofu

Truck being parked in the same place each time. This picture shows some driveway damage caused by the Tofu

Truck being parked in the same place each time. The area pictured here are where the front tires usually sit. This seems to be the area of most pronounced damage.

The area pictured here are where the front tires usually sit. This seems to be the area of most pronounced damage. So the solution is to build a concrete pad big enough for the Tofu truck with the blade attached and possibly some overlap. It was

determined that dimensions of 10'x24' would be best. This cement mixer cost me $50 on Craigslist.

So the solution is to build a concrete pad big enough for the Tofu truck with the blade attached and possibly some overlap. It was

determined that dimensions of 10'x24' would be best. This cement mixer cost me $50 on Craigslist. This is what one 10'x8' section looks like. The area covered so far is where the rear wheels usually sit. The damage was almost as bad

as where the front wheels sit. This section took 47-80 lb. bags of crack-resistant concrete. You can see why I didn't want to do this

without a cement mixer. Also, doing the job in sections enables me to test the quality of my work without committing too many resources.

This concrete takes 28 days to cure to full strength which should be on 4/15/10. At that time I will park the Tofu Truck's front wheels

on the pad for a couple of weeks. Driving on and off the pad, plus parking, should tell me whether I got it right. If no cracks develop

after several weeks of commercial use, then that is a good sign.

This is what one 10'x8' section looks like. The area covered so far is where the rear wheels usually sit. The damage was almost as bad

as where the front wheels sit. This section took 47-80 lb. bags of crack-resistant concrete. You can see why I didn't want to do this

without a cement mixer. Also, doing the job in sections enables me to test the quality of my work without committing too many resources.

This concrete takes 28 days to cure to full strength which should be on 4/15/10. At that time I will park the Tofu Truck's front wheels

on the pad for a couple of weeks. Driving on and off the pad, plus parking, should tell me whether I got it right. If no cracks develop

after several weeks of commercial use, then that is a good sign.

|

| 02/25/10 |

Here is the welder I purchased a couple of weeks ago, a 140 amp 110 volt MIG welder. MIG stands for "metal-inert-gas." A metal wire feeds

out the center of the wand and makes contact with the area to be welded thus completing an electric circuit. Normally some sort of shielding

gas needs to be used because the temperatures generated at the point of contact cause the oxygen in the air to react with the pieces being

joined. This reaction creates a "cold weld" joint which is inherently weak. So an inert gas (argon, carbon dioxide, or a mixture of the

two) is expelled around the contact point pushing the air containing oxygen out of the way thus creating a better weld. The problem with

using gas as a shield takes place outdoors on a windy day because the shielding gas doesn't remain around the work area long enough. The

solution is to use flux-core wire instead of solid wire and shielding gas. Flux core wire has an inert core which does the same thing as

shielding gas.

Here is the welder I purchased a couple of weeks ago, a 140 amp 110 volt MIG welder. MIG stands for "metal-inert-gas." A metal wire feeds

out the center of the wand and makes contact with the area to be welded thus completing an electric circuit. Normally some sort of shielding

gas needs to be used because the temperatures generated at the point of contact cause the oxygen in the air to react with the pieces being

joined. This reaction creates a "cold weld" joint which is inherently weak. So an inert gas (argon, carbon dioxide, or a mixture of the

two) is expelled around the contact point pushing the air containing oxygen out of the way thus creating a better weld. The problem with

using gas as a shield takes place outdoors on a windy day because the shielding gas doesn't remain around the work area long enough. The

solution is to use flux-core wire instead of solid wire and shielding gas. Flux core wire has an inert core which does the same thing as

shielding gas.

This was the purpose of my wanting to be able to weld in the first place - to repair some of the rust damage on the Tofu Truck (left.) These two

pieces were actually cut-up pieces from my old snow plow blade. In other words, rather than just throwing out the old blade, it was

recycled. In the picture at right, the orange-colored piece of metal is the new blade. The "wing" painted gray is a piece of the old blade

as well. These wings were added to each corner of each plow blade to protect the high-wear points on the cutting edge and were inspired by

a wrap-around now built in to many new plow blades.

This was the purpose of my wanting to be able to weld in the first place - to repair some of the rust damage on the Tofu Truck (left.) These two

pieces were actually cut-up pieces from my old snow plow blade. In other words, rather than just throwing out the old blade, it was

recycled. In the picture at right, the orange-colored piece of metal is the new blade. The "wing" painted gray is a piece of the old blade

as well. These wings were added to each corner of each plow blade to protect the high-wear points on the cutting edge and were inspired by

a wrap-around now built in to many new plow blades.

Why bother doing this instead of buying brand new steel? Steel is expensive! How expensive? See the crosspiece on the sawhorse at left

(closeup at right?) That 4' piece of perforated steel cost $6.51 at Home Depot. Can you imagine what a piece of steel like that used to

repair the dump truck would cost if I had to buy it new at Home Depot (if I could even get it?)

Why bother doing this instead of buying brand new steel? Steel is expensive! How expensive? See the crosspiece on the sawhorse at left

(closeup at right?) That 4' piece of perforated steel cost $6.51 at Home Depot. Can you imagine what a piece of steel like that used to

repair the dump truck would cost if I had to buy it new at Home Depot (if I could even get it?)The only thing wrong with the old blade was it was worn down to the mold board (scoop) part of the plow and there was some minor surface rust. If you cut the metal into pieces as I did you will see that the cross-section of the steel is solid. Now about these sawhorses. I had the crutches which, by the way, I rescued from a dumpster thinking they may be worth something. I asked my wife, a nurse, what I could get for them? She said I would be lucky to get $5. I started advertising them on Craigslist for $10. Nothing. I lowered the price to $5. Nothing. I lowered the price to zero and put them under the category "free stuff." Guess what? Right. Nothing. Just before I was about to put the crutches back in the dumpster I started to ask myself what I could make out of them, hence, the sawhorses. The pieces of PVC cost $2.00 and the metal straps used to fashion them into hinges cost $1.00. I discovered a way to eliminate the plastic pieces and use pieces of round wooden handles from tools that broke, saving the $2.00 and the plastic. And here are a metal warning bar that got mangled and rather than try to straighten out the mangled part I just cut it out and welded the two pieces back together. Also the original wheelbarrow handles rusted off so I took these two handles off another wheelbarrow where another part was rusted and bolted the handles from one onto the body of the other, then welded the reinforcing bar between them:

|

| 01/04/10 |

Remember a couple of years ago I was talking about taking a welding class? Well actually I took two of them. The first class covered the

basics of arc (stick), MIG, TIG, torch welding and braising, and plasma cutting. The second class, which ended the Monday before

Christmas covered more of the same, and we covered what kind of welding might be best suited for what kind of application plus different

techniques for joining two different pieces of metal. Needless to say I am hooked. Further, I've committed the funds from my landscaping

business to buy a welder. The one I am looking at is a 140 amp MIG welder (the most powerful one you can get that runs on 110V) which

includes a cart and will cost $480, including shipping.

Remember a couple of years ago I was talking about taking a welding class? Well actually I took two of them. The first class covered the

basics of arc (stick), MIG, TIG, torch welding and braising, and plasma cutting. The second class, which ended the Monday before

Christmas covered more of the same, and we covered what kind of welding might be best suited for what kind of application plus different

techniques for joining two different pieces of metal. Needless to say I am hooked. Further, I've committed the funds from my landscaping

business to buy a welder. The one I am looking at is a 140 amp MIG welder (the most powerful one you can get that runs on 110V) which

includes a cart and will cost $480, including shipping. I already did my first practical project in class. These pictures are of a snowplow pin that I repaired. To buy one new cost $31 last year.

The tip broke off. I found a piece of metal bar (just lucky) that was the exact diameter of the original pin and was able to grind and bevel

the two pieces to the correct angles so the weld would be of optimum strength. Now the picture of the repaired pin is longer that would

be usable so should I need to put it into service I can cut it to the correct length and bevel the tip like the original.

I already did my first practical project in class. These pictures are of a snowplow pin that I repaired. To buy one new cost $31 last year.

The tip broke off. I found a piece of metal bar (just lucky) that was the exact diameter of the original pin and was able to grind and bevel

the two pieces to the correct angles so the weld would be of optimum strength. Now the picture of the repaired pin is longer that would

be usable so should I need to put it into service I can cut it to the correct length and bevel the tip like the original.

|

| 12/01/08 |

Another one bites the dust! Remember that restaurant in Nashua that ran their diesel-powered VW Beetles on their own WVO? Well, a couple of weeks ago when I was driving by with my wife she noticed the place was closed and had a "for sale" sign in the window. I called the cell phone number I had for the owner and he confirmed, in fact, that the restaurant was for sale, but he neglected to tell me the reasons. I wouldn't want to talk about it either if I was having trouble. Anyway, it was a good restaurant and I am disappointed in their closing shop for many reasons. |

| 11/24/08 |

There are a couple of new developments here. 1) My most recent supplier of veggie oil, a hot dog place with three restaurants in the area, has succumbed to the economy and gone out of business. This is especially sad not just because I got my oil from them for free when others had begun to charge me, but they had been in business since 1920. 2) Since crude petroleum prices have fallen by two-thirds and gasoline and diesel has fallen in price by at least fifty percent, perhaps those restaurants that were getting paid for their old oil won't get paid anymore and I will get some local suppliers who will give me their oil again. If you or any regular viewer of this column knows of a restaurant in the greater Hudson, NH area who will part with their old oil and won't charge me, please let me know place and contact information. |

| 09/18/08 |

I am experimenting with different blends of WVO/diesel to see if I can get some extra mileage

out of my fuel filters. Also, I've discovered that some parts of the country do not have the same demand for WVO as southern New Hampshire. As a result, I may be able to pick up a rather large volume of the stuff and still not have to pay for it like I do around here. |

| 07/13/08 |

One of my suppliers of WVO had a big fire a couple of months ago and it doesn't look like

they are going to rebuild, so I had to locate some other suppliers. Also that ham radio friend mentioned earlier helped me install the replacement panels on the Tofu Truck. I need to finish the job. I will probably pick up a small welder and play with it, perfecting my technique. When all the body panel work is done I will probably repaint the whole cab of the truck from the red it currently has to the same green of our company t-shirts and yard signs. I will also paint the Nissan to match. Some of the paint is peeling off down to the primer, but it is not rusting. Curious. Then I will have both trucks professionally lettered. One of my customers does that kind of work, so we will probably trade service for service. |

| 05/22/08 |

Hallelujah! Here is a shot of the completed installation. I already had pieces of fuel line so the

only issue was how to actually insert the warmer between the existing fuel line and the fuel

filter. I bought these adapters and was looking for some hard line similar to what feeds the

filter. Then I realized I have enough hard line already in the system such that all I had to

do was sever the line and attach adapters with compression seals to the two exposed ends. Then

I just screwed in the fuel line nipples to the adapters, et voila!

Hallelujah! Here is a shot of the completed installation. I already had pieces of fuel line so the

only issue was how to actually insert the warmer between the existing fuel line and the fuel

filter. I bought these adapters and was looking for some hard line similar to what feeds the

filter. Then I realized I have enough hard line already in the system such that all I had to

do was sever the line and attach adapters with compression seals to the two exposed ends. Then

I just screwed in the fuel line nipples to the adapters, et voila!

As of this writing the Tofu Truck has been running on FWVO through the inline fuel warmer for about 30 minutes. I periodically go out and check for leaks. |

| 05/21/08 |

The fuel line warmer has been installed, except for hooking up the fuel line.

The fuel line warmer has been installed, except for hooking up the fuel line. I simply unhooked one hose going to the tank warmer and spliced in an extender and hooked up the

extension to one end of the warmer. Then I cut another section of hose and attached the other end of

the inline warmer to where the tank heater used to be connected. I am still trying to determine the

best way to hook up the fuel lines.

I simply unhooked one hose going to the tank warmer and spliced in an extender and hooked up the

extension to one end of the warmer. Then I cut another section of hose and attached the other end of

the inline warmer to where the tank heater used to be connected. I am still trying to determine the

best way to hook up the fuel lines. The input line to the fuel filter is actually metal so we will probably need some kind of a

compression seal union to a standard fuel line nipple.

The input line to the fuel filter is actually metal so we will probably need some kind of a

compression seal union to a standard fuel line nipple.

I will browse at Home Depot tomorrow to see what they have. I think they do sell something with compression seal fittings on one side and I forget what is on the other side. |

| 05/18/08 |

Based on the planned location of the warmer, it was not going to work having the coolant nipples sticking

straight out to the side. So I went to Home Depot to pick up some brass elbows which you see in this

picture:  You can also see what the fully-assembled fuel warmer looks like (minus the teflon tape at the joints) before installation. I am also investigating what it would take to simply unhook the fuel input to the filter (#1 in the picture below), splice on an extender and route that new section to a fuel input nipple on the warmer, then run a line from the other fuel nipple on the warmer back to the fuel filter. |

| 05/15/08/08 |

Here is what the old water separator looked like:  A couple of years ago when the water separator needed replacement, Ford couldn't get the part due to the

age of the truck so they retrofitted a combination fuel filter and water separator unit:

A couple of years ago when the water separator needed replacement, Ford couldn't get the part due to the

age of the truck so they retrofitted a combination fuel filter and water separator unit:

To me, this was a good call. This

unit replaces the plain fuel filter at this exact location. Replacing a cartridge is a 15 minute

procedure, including bleeding the air out of the system. To me, this was a good call. This

unit replaces the plain fuel filter at this exact location. Replacing a cartridge is a 15 minute

procedure, including bleeding the air out of the system.Here is the new inline fuel warmer I took possession of today  It is made by the same people who made the tank heater It is made by the same people who made the tank heater

These are some of the auxilliary parts

for the fuel warmer These are some of the auxilliary parts

for the fuel warmer  We will also need

a section of fuel line to replace the hard plastic line currently feeding the filter. Unfortunately

Ford did not make the lines more flexible, otherwise we could just route the line currently feeding

the filter into the line warmer and just use a new section of fuel line to go from the line warmer's output

to the fuel filter input. Here is what the warmer looks like with the parts in place We will also need

a section of fuel line to replace the hard plastic line currently feeding the filter. Unfortunately

Ford did not make the lines more flexible, otherwise we could just route the line currently feeding

the filter into the line warmer and just use a new section of fuel line to go from the line warmer's output

to the fuel filter input. Here is what the warmer looks like with the parts in place

|

| 05/01/08 | Between the last posting and now I've upgraded the fuel filter in my refinery to a 10 micron filter. Surprisingly I do not appear to be getting that much better yield from the fuel filter/water separator in the Tofu Truck. It may be a little better but not nearly what I would expect. Here is my theory: Between the tank and the fuel filter the fuel tends to cool down significantly thus impeding the filtering capability of the truck's filter. Solution: Add more fuel line heating. |

| 04/05/08 |

A friend of mine who I know through ham radio has

agreed to teach me how to weld. I offered to pay him for his time either in cash or barter. He

restores old Chevy Novas from 1963-1967 vintage. I can get about 50 gallons of FWVO through a fuel filter before the filter needs to be replaced. The WVO is filtered down to about 25 microns before being introduced to the Tofu Truck. Supposedly a fuel filter will pass particles 10 microns or smaller, so theoretically if I filter the WVO down to that size, I should get dramatically longer fuel filter life. Here's the question, though: how much would it cost me to do that? Right now I pay about $3 per filter in the refinery and $18 per fuel filter in the Tofu Truck. I can get about 50 gallons through the refinery filters before they need replacement. How much would refinery filters cost if they had a 10 micron rating? How much WVO could I get through those before they would need replacement? Any ideas? |

| 03/15/08 | Initially that welding class was supposed to start Tuesday, March 4th. The start date was postponed to Tuesday, March 11th. Now it is cancelled altogether due to lack of enrollment. I plan to see if a local community college or tech school offers a welding program I can participate in. Failing that, I will see how much the instructor would charge me to teach me one-on-one or in a small group. He's the person whose company has already done some welding on the Tofu Truck. His company re-did the trailer hitch. Wish me luck, please. |

| 02/19/08 |

This is not directly related to alternative energy, but it does relate to the Tofu Truck: The driver side cab body is starting to rust beyond the point where Bondo will do any good. Further, I was down at the place where my clutch was replaced and they took care of a power steering leak. While I was there I asked the auto body shop next door for a quote to repair the rust and without giving it too much thought the fellow said the repair would cost upwards of $5,000. Ouch! Needless to say he advised not doing the work. Certainly I would agree with him with a price tag like that. Well, not being one to give up easily, our local high school has a wonderful vo-tech program including some adult-ed classes. I signed up for their welding class at a cost of $75. The fellow teaching the class was the guy who did some bumper repair work on the dump truck already. I can buy a welder at Sears for anywhere from $235 to $2,100. They also have gasoline-powered welder and welder/generator units from $1,250 to $2,900. Even if I spring for the most expensive welder Sears has, plus all materials and safety gear, I will save at least $2,000 and will end up with a neat tool! Of course, one of the questions I plan to ask the instructor is what kind of unit is best for what I am doing. |

| 01/25/08 |

I got the Tofu Truck back after having a new clutch installed, plus new hydraulic hoses for the plow,

rewiring for the headlights and a new engine block heater for those cold mornings. As you can tell,

this is a work truck and it shows that use of WVO is practical on a day-to-day basis. Ask yourself

who would object to this, that is, who stands to lose if you can go to your corner fueling station

and fill up with vegetable oil as easily as you now fill up with diesel or gasoline? 'Nuff said? |

| 01/07/08 |

Please support HB1355FN! When: Wednesday, January 9, 2008 Time: 1:30 PM Place: Room 201 Legislative Office Building Concord, NH HB1355FN will waive the state's road toll (gasoline tax) on vehicles that run alternative and renewable fuels, including but not limited to biodiesel, vegetable oil, waste vegetable oil, ethanol, etc. For more information, please call Rich at 617-794-0007 (Verizon Wireless) or email me here. |

| 12/08/07 |

This display shows the modifications to the refinery and its location after being moved indoors:

The pictures are, from left to right, 1) This is the new 1/2 hp pump. The 1/12 hp pump in the old refinery is getting a little tired. This is possibly due to my abusing it, and I don't mean just the running of WVO through it. 2) This is the refinery with the new pump and showing the replacement of the PVC with clear, flexible tubing. 3) This shows the sediment tank in the garage. 4) This shows the location of the complete refinery and sediment tank with respect to each other and in the garage. 5) This shows where I keep a few jugs of FWVO to keep it relatively out of the way and warm enough to pour when needed. I have this many more outside. |

| 10/15/07 |

Here is the latest: for the past week since I last replaced the fuel filter and water separator on 10/8/07,

I've been running just on oil from the new sediment tank. This morning the temperature was 34F. I warmed

up the truck and switched over to vegetable oil while the truck was still idling on the driveway just to

make sure there were no glitches, hitches, or b@#$hes. I drove the Tofu Truck from Hudson, to Manchester, to Nashua and back to Hudson, a total of 41 miles today with nary a hesitation. I've put in several hundred miles since the last filter change. The sediment tank has been moved in to the garage right next to the refinery, given the cold weather. I am going to see how many miles I get on this fuel filter. If I get a year, then I probably will not do anything different. If I get less than six months on this fuel filter, then I will try running the output from the sediment tank through the refinery and see what that does. Warmup is definitely key to maximizing power and minimizing hesitation and stalling. |

| 10/04/07 |

For those of you who did "stay tuned," here is what you have been waiting for. The pictures above are, from the left: \ These are a bunch of the 35 lb jugs *previously* used to store both the unfiltered and filtered WVO. An equal number of empty jugs were just delivered to the curb for recycling. I still have plenty of clean empties. This is the sediment tank. As mentioned below, it cost less than half what the refinery cost and it uses zero energy. It is what enabled me to recycle all those empty 35 lb jugs. These are the valves. The "good oil" valve is located three inches above the "crap" valve. About 24 hours after a full load of WVO is placed into the tank, I expect I will be able to draw reasonably clean WVO from the top valve. Once the top valve no longer provides oil, then the remaining contents of the tank are removed from the bottom valve. As a serendipity, these valves are compatible with the intake hose of the refinery. This is one of my garage doors. What does that have to do with alternative energy? Glad you asked. Perhaps you noticed the bottom two sections of the door look a little different than the top two, excluding the fact the top section has windows. Well the bottom two sections were rotting out. The garage door people told me one section of the door would cost $190 not including installation. I built two sections for about $20 in parts and a day's labor. See those pieces I cut out of each section to make the four panel appear close to the original? There were eight of them. Three of them were used to make the vertical parts of the base supporting the sediment tank in the second picture. See? We're all about recycling. |

| 09/19/07 |

I am reading a book called "The Ultimate Gift" by Jim Stovall. I just started the book this

morning and I am already on page 60, even though I've been doing other things on and off

throughout the morning. Page 60 is the start of Chapter 7, "The Gift of Problems." Why is that relevant to the Tofu Truck? Well, I started having problems with hesitation and stalling, even though the fuel filter and water separator were replaced less than two weeks ago. That is clearly a problem. Why is it a gift? Well because it caused me to think. Thinking about what one is doing, even in the face of adversity, is what makes it a great gift. If you've read all the items on this page, you know what I paid for the "Refinery" in terms of time and money. You know the technical specs to which I am filtering the WVO. You know what I know. What you may not know is the experience I had which lead me to stopping by Home Depot in Londonderry, NH last night and analyzing how I would implement an inspiration I had. Clearly, something is plugging up my fuel filters. The question is how do I filter it better? Do I simply buy a more powerful pump and finer filter? Well, that would be one way. It would certainly be more expensive and the operation of such a device would waste more energy. Or, I could take a step back an analyze what I had learned so far. One thing I noticed from experience which chances are I could not have learned from a book (I had to see it for it to make an impression) was even after filtration, there was a significant amount of guck (that's a technical term) on the bottom of the jugs used to store the FWVO. The oil on top was relatively clear. So my inspiration resulted in a design for a filtration system which would cost less than half my investment in the "Refinery," and would use no energy. Stay tuned if you want to know what it is. |

| 09/11/07 | Now I have a track record, albeit short, of running the Tofu Truck with a tank heater. You will note back in October of last year I had some trouble switching over to WVO even on warm days. In hind sight, what was most likely happening was the fuel filter got clogged because I tried to run the truck when the outside temperature was too cold. Once that happened, it is extremely difficult to flush out the sludge. That is one reason why I replaced the fuel filter even though it was replaced only five weeks earlier. Now I am at a wait-and-see point as to how much time I have before the fuel filter needs to be replaced again. If the weather gets cold enough, I will install a separate fuel line heater between the fuel selector switch and the fuel filter. |

| 09/06/07 | Today was the first full successful day of testing with the new HotFox installed. I also changed the fuel filter/water separator although it was just about 5 weeks ago I last changed it. Now with the thinner viscosity of warmer fuel I am expecting to get at least a year before I have to change the filter again. I will be hooking up the fuel line in the front tank to the fuel outlet on the HotFox shortly which will assure warmer fuel entering the filter. Stay tuned! |

| 09/05/07 |

Remember how I did not hook up the fuel line to the open port on the tank heater? Know how most fluids expand when heated? Know how most vehicle fuel tanks are pressurized to some extent anyway? Are you getting the picture? OOPS! D'Oh! When I stopped at a repair garage (having new front springs put in) there was a significant puddle of oil on the ground. Fortunately that is one serendipity of running a vehicle on veggie oil. A spill is a minor inconvenience rather than a major ecological disaster. So I bought a section of fuel line I will need, put the correct nipple in the tank heater and attached the fuel line. I clamped it down tight and put a plug in the other end and clamped down tight, too. It is getting dark and I do not feel like crawling around under the truck with a droplight to hook up the other end. At least I can run the dump truck on the front tank without leaving an oil slick behind me. The fuel line has been coiled and wire-tied to the existing fuel lines, waiting for me to hook it up the next chance I get. |

| 09/04/07 |

To make a long story a little bit longer, I actually decided to add valves to the T-connectors

pictured below. I was thinking about it in terms of the directions specifying having a valve

to stop flow to the tank heater under certain conditions, and said, "Better to have it and not

need it, than..." Actually I installed the T-connectors with valves last night and made sure

they held the coolant. Then that was one less thing I had to test.

To make a long story a little bit longer, I actually decided to add valves to the T-connectors

pictured below. I was thinking about it in terms of the directions specifying having a valve

to stop flow to the tank heater under certain conditions, and said, "Better to have it and not

need it, than..." Actually I installed the T-connectors with valves last night and made sure

they held the coolant. Then that was one less thing I had to test.

I had bought 22' of hose as stated before, but because I did not take up the slack in the first

section of hose before cutting it, I left myself about a foot and a half too short for the

second section of hose. Fortunately I had a spare section so I could splice it in.

I had bought 22' of hose as stated before, but because I did not take up the slack in the first

section of hose before cutting it, I left myself about a foot and a half too short for the

second section of hose. Fortunately I had a spare section so I could splice it in.

And of course, here is what the heat exchanger looks like once installed in the front fuel tank.

The fuel line is not (yet) hooked up to the Hot Fox directly, but the Hot Fox can still do a

bang-up job heating the WVO in the tank, which is what this is all about.

And of course, here is what the heat exchanger looks like once installed in the front fuel tank.

The fuel line is not (yet) hooked up to the Hot Fox directly, but the Hot Fox can still do a

bang-up job heating the WVO in the tank, which is what this is all about.

|

| 09/02/07 |

I had an epiphany, so I went down to Home Depot in Londonderry, NH, to do a little browsing for ideas.

I love the fact HD is open on holiday weekends. Anyway a quick trip down memory lane (the plumbing

aisle) yielded the results I was looking for. There were a couple of threaded brass MIP to barb connectors,

with the barbed (nipple) size at 5/8" and the MIP side at 1/2" (the array of six items on the right.)

It did not take long to find a 1/2" cast, threaded T to go with them (the two items on the left.)

I had an epiphany, so I went down to Home Depot in Londonderry, NH, to do a little browsing for ideas.

I love the fact HD is open on holiday weekends. Anyway a quick trip down memory lane (the plumbing

aisle) yielded the results I was looking for. There were a couple of threaded brass MIP to barb connectors,

with the barbed (nipple) size at 5/8" and the MIP side at 1/2" (the array of six items on the right.)

It did not take long to find a 1/2" cast, threaded T to go with them (the two items on the left.)

This is what they look like assembled. I will be using teflon tape at the joints before final

installation.

This is what they look like assembled. I will be using teflon tape at the joints before final

installation.

And of course, here are the spiral clamps I will be using to fasten the heater hoses to the T connectors

and to the heat exchanger.

And of course, here are the spiral clamps I will be using to fasten the heater hoses to the T connectors

and to the heat exchanger.

|

| 09/01/07 |

This is 22' of 5/8 heater hose. Probably more than I will need, but I would rather have too much than

not enough. I will need two sections of heater hose to run from the two coolant ports on the heat

exchanger to two "T-connectors" I plan to install on the heater hoses in the Tofu Truck. I will also

need several spiral clamps to fasten the hose at each of the three nipples on each T-connector as well as

at the heat exchanger.

This is 22' of 5/8 heater hose. Probably more than I will need, but I would rather have too much than

not enough. I will need two sections of heater hose to run from the two coolant ports on the heat

exchanger to two "T-connectors" I plan to install on the heater hoses in the Tofu Truck. I will also

need several spiral clamps to fasten the hose at each of the three nipples on each T-connector as well as

at the heat exchanger. This is the fuel line nipple. It will screw into the fuel line adapter I bought from the dealer (see

picture below.) It should accomodate the fuel line already in the truck. I say "should"

because I may need a longer section of fuel line than what is factory stock, given the planned location

of the heat exchanger on the fuel tank. In addition to the heat

exchanger heating the WVO in the tank, fuel drawn up through the heat exchanger is heated more.

This is the fuel line nipple. It will screw into the fuel line adapter I bought from the dealer (see

picture below.) It should accomodate the fuel line already in the truck. I say "should"

because I may need a longer section of fuel line than what is factory stock, given the planned location

of the heat exchanger on the fuel tank. In addition to the heat

exchanger heating the WVO in the tank, fuel drawn up through the heat exchanger is heated more.

Interestingly enough, finding a 5/8" T-connector is not as easy as it sounds. You see, my intended application is "non-standard." This means the above parts which I bought at a local auto parts store are intended to, perhaps, repair a broken heater hose on a vehicle, which already has the appropriate connectors already installed. Vehicle manufacturers do not intend people to "tap in" to the heater hoses on their vehicles and install stuff like this. It is more common on heavy trucks which is why the dealer is set up for things like this and why they would be ready, willing, and able to do the install if I had a tractor-trailer rig or LARGE dump truck. Places like Home Depot have plenty of plumbing connectors that would work, because it is not uncommon for people to need connectors to divert water in various applications, but they sell what they need. So they have PVC T-connectors in 1/2" and 3/4", but not 5/8". They also have a very nice brass 5/8" splicing connector (just two ports) but not a T-connector (three ports.) My next step is to contact the truck place to see if they have the T-connector I am looking for. If they do not, there is a specialty hose and coupling place which may have the connectors I am looking for. Stay tuned for more info. |

| 08/30/07 |

The tank heater has arrived!!! Here are a couple of pictures of the tank heater and associated parts.

The tank heater kit (top picture) consists of the heat exchanger (top) parts such as gaskets, screws,

and extenders (lower left) and instructions (lower right.) The instructions for installation are geared

primarily for large trucks, so illustrations tend to be relative to those big, cylindrical fuel tanks on

those large tractor-trailer rigs. I am probably going to have to figure some things out on my own.

The tank heater has arrived!!! Here are a couple of pictures of the tank heater and associated parts.

The tank heater kit (top picture) consists of the heat exchanger (top) parts such as gaskets, screws,

and extenders (lower left) and instructions (lower right.) The instructions for installation are geared

primarily for large trucks, so illustrations tend to be relative to those big, cylindrical fuel tanks on

those large tractor-trailer rigs. I am probably going to have to figure some things out on my own. Here is a top view of the heat exchanger.

Here is a top view of the heat exchanger. Here are a couple of connectors I bought from the dealer when I picked up the tank heater kit. The two

fittings on the left screw into the ports labeled "coolant" and the fitting on the right will accomodate

a fuel line nipple.

Here are a couple of connectors I bought from the dealer when I picked up the tank heater kit. The two

fittings on the left screw into the ports labeled "coolant" and the fitting on the right will accomodate

a fuel line nipple.The dealer is a heavy truck dealer and as such admitted to not having experience installing these kits in my "little" F350 diesel dually. I wanted to have them do the install so I wouldn't have to spend the time, but I think they chickened out. I am not mad at them and would continue to buy parts from them. It is just not their core experience. It is not mine either :-) |

| 08/16/07 | The tank heater has been ordered. The parts manager told me the lead time was one week, which means we should expect two weeks. Hey, if it comes sooner, so much the better. I would rather be pleasantly surprised than unpleasantly surprised. I will post pictures when the parts come in, then I will chronicle the installation as well. |

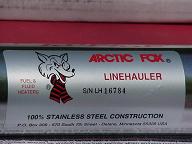

| 08/10/07 | I emailed the local truck place who happens to be the area dealer for the Arctic Fox line of tank and fuel line heaters. I requested the Hot Fox HFG10-12 (fits in 10"-12" deep fuel tanks) and all associated plumbing. The parts manager says I am looking at around $220 for the parts. He is now looking in to the lead time. Stay tuned. |

| 08/07/07 | I had the same problem after the new sending unit was installed. So I raised heck (nicely) with the dealer. I explained that after $338.34 the problem should be fixed. I told them if they road tested the truck like I would expect, the problem would have been obvious. So they took the truck back and basically did angioplasty on the front fuel lines and that seems to have corrected the problem. I am now running FWVO again. |

| 08/06/07 | The dealer takes a look at the front tank and determines there is a problem with the sending unit. They also cleaned out some gunk (fat?) that had accumulated around the intake screen. $338.34 later and I figured it at least should run well, right? WRONG! |

| 07/31/07 | I've been having a challenge with the front tank. I drained the front tank completely, then I filled it with petroleum diesel. I am still having a problem with the front tank. I can't figure it out. |

| 03/25/2007 | The latest issue has been my quest to obtain and install fuel tank and fuel line heaters so I can run FWVO year round. Fuel line heaters are not a big deal, but the fuel tank heater is a different story. Given the age of my truck (1987) Ford does not stock replacement fuel tanks. so when I had the front tank replaced last year, I could not get detailed specs on whether the tank had baffles in it, and if so, where those baffles were located. This is an important question because it determines placement of the heater. I am looking primarily at the Arctic Fox brand of coolant-operated tank heater. Radiator coolant would be diverted and circulated through the tank-mounted heat exchanger. I am also considering an externally mounted 12V electric tank heater. This would operate similar to an electric blanket. I will post any findings here. |

| 10/11/2006 |

Still more problems. I performed the usual warm-up procedure on the petroleum diesel in the rear

tank, then after about three miles I switched to the front tank. I got further this time, but

there still is a challenge. There was lots of hesitation and at some points I thought the engine

would stall. So I switched back to the rear tank and ran that way for the rest of the day. When I got back to the shop, I added more Diesel Therapy to the front tank. I am hoping that this will flush out whatever is wrong. There are several theories I am going on. One, the WVO from Kingston is a different formulation. Two, it is just dirtier than the WVO from Hudson (which I don't understand, because I pass it through the same 25 micron filter.) Three, the wVO got contaminated somehow (it was sitting outside for a couple of days before I picked it up. The containers were, however, sealed with screw-on caps.) And four, the option I really don't want to consider but I have to for this to be a fair test. Something is building up as a result of this experiment and I would need to figure out what and why. I tend to doubt this, though, because after a few miles of running on the rear tank only, the truck returns to normal. Once I get the front tank flushed out, I will try going back to oil from the Hudson restaurant only. Stay tuned. |

| 10/10/2006 |

Not good news. I put two jugs of WVO in to the Tofu Truck's front tank. Then I went to the station

on the corner (about one mile away) and put in $11.00 worth of petroleum diesel (about 4.2 gallons)

while the truck was idling. I then drove another two miles to make sure the Tofu Truck was fully

warmed up. Then I switched over to the front tank. Less than five miles down the road, I started

experiencing some serious hesitation. I immediately switched back to the rear tank. I thought the

truck was going to stall. It almost did a couple of times. I made it to Haffner's in South Hudson

and filled the front tank with petroleum diesel, hoping to avoid further problems. When I got back to the shop, I put in the recommended dose of CRC Diesel Fuel Therapy in both tanks. Tomorrow will be another day. |

| 10/7/2006 | I just picked up three 35 lb. buckets of WVO from a different restaurant run by friends of ours in Kingston, NH. I do not expect the truck to behave differently with the oil from this restaurant than it does with the oil from the restaurant in Hudson. For the past week, I have been doing my usual landscaping route pulling a modified trailer behind my dump truck instead of the trailer I usually pull behind my Nissan. As always, I run exclusively on the WVO or blend, except for the warmup and cooldown periods at the beginning and end of the day, respectively. |

| 10/3/2006 | I put the last 4 gallons of WVO in the front tank and automatically added about another 2 gallons of petroleum diesel. I drove about another mile and switched over to WVO and there have been no more problems running on WVO. So the moral of the story is, if nighttime temperatures get to the middle to upper 30s (degrees Fahrenheit), it is a good idea to run WVO to petroleum diesel at a ratio of about 2 to 1. Keep in mind I still have not invested in a tank and fuel line heater. I have not even priced one out, but I will. In the meantime, I will continue to experiment with different mixtures of WVO to diesel the colder the nighttime temperatures get. It is still a good deal. |

| 10/2/2006 | I thought I let the dump truck warm up enough, and I don't even know if that was the problem, but what happened was I drove about 2 miles before switching to WVO and the truck started hesitating. I switched back to petroleum diesel and the truck still died. Fortunately, I was able to get it started again, but I didn't have the nerve to switch back to WVO. I stopped at a Sunoco station and picked up two gallons of petroleum diesel in the WVO tank. The truck was now just a little bit more warmed up, too. No more worries either. |

| 9/27/2006 |

CAUTION!!!

CAUTION!!!Don't let this happen to you. These are two filters from my "refinery". The one on the left has filtered about 20 gallons of WVO, but then I let it get cold. This is why you need to switch back from WVO to petroleum diesel a couple of minutes before you shut the engine down. The only time you do not need to do this shutdown procedure is if the engine was fully warmed up and has been shut down less than two hours before on a warm day! The shutdown time available to you without switching back to petroleum drops dramatically the colder the weather gets. If you do not observe the procedure of switching back to petroleum diesel a few minutes before shutting down, your fuel filter will look like this. Stay tuned. I am experimenting with different procedures, i.e. keeping the FWVO25 in a warm area to reduce gelling. I am also experimenting with running some fresh SVO through the "refinery" to flush things out after the last filtering of the day. |